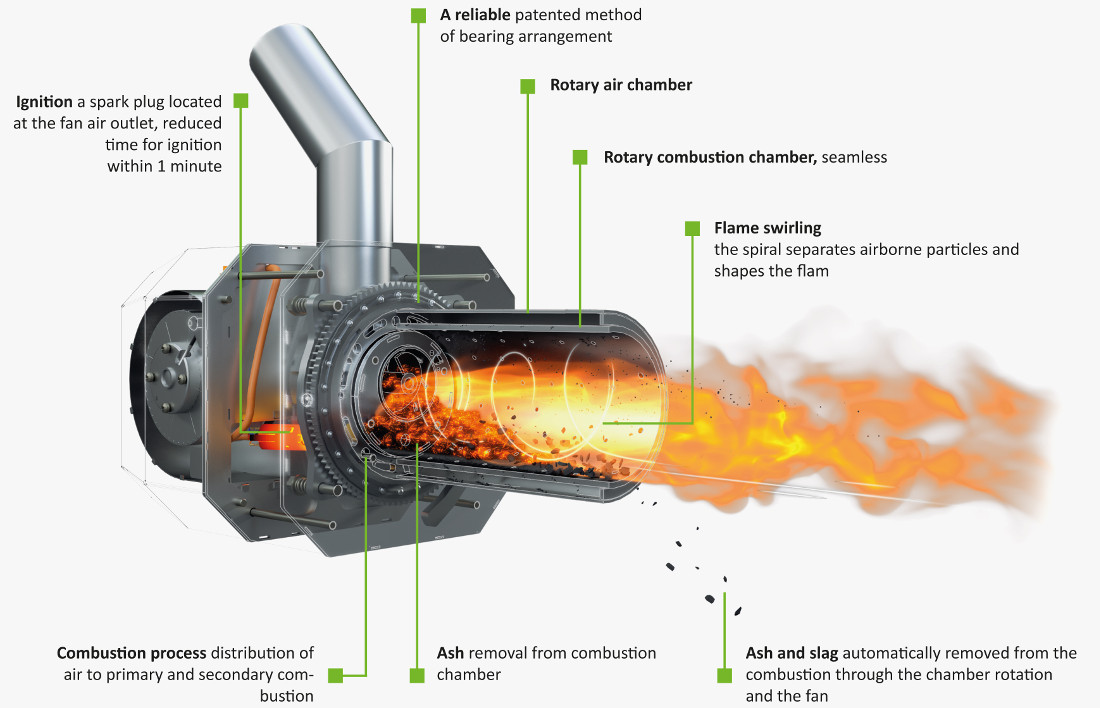

Patented solution of rotary burner with self-cleaning combustion chamber with maximum care about details. Burners BLAZE HARMONY are characterized by the highest quality of workmanship using innovative cleaning mechanism which is differentiate these burners from many similar products on market. This solution does not mean only user’s comfort, resulting from the time savings, when it does not have to clean the burner, but it means also possibility of burning lower quality pellets without operational problems, that would otherwise arise during the combustion.

Pellet burners BLAZE HARMONY allow you to optimize the heating processes and contribute to economic and operational advantages. Especially reducing the heating costs and maintenance.

Maintenance-free solution for burning pellets. It is sufficient to check it before heating season.

4 mm at its thinnest point. Only the burner without welded parts (back cover plate of chamber, cogwheel, sealed bearings.

Very simple and fast instalation and service of the burner. Quick acces to all components.

Patented system. The longitudinal ball bearings transfer radial loads, ensuring smooth operation of revolutions of the burner, without any abrasion of metal/metal – load transfer at least on 50 balls (according to the size of burner). For user and service that means hihg service life (lower load of the bearings) and no abrasion of burner’s metal parts.

Automatic cleaning of aeration chamber is common turning of combustion and aeration chamber. This method of automatic cleaning completely eliminates the need of manual cleaning. This eliminates periodic disassembling of the burner and service.

Patented mechanism, which ensures highest efficiency of combustion and possibility to set optimal combustion of various kinds of pellets. By the output 18 kw, there it is set fixed, from output 26 kW, there is an option to regulate it thanks to the flap.

With this system all problems are eliminated, and proces of combustion is optimized by distribution of primary and secondary air.

There is an air curtain used in combustion chamber. This reduce the transfer of heat to burner and it means conservation of heat in the combustion chamber.

... on which it relies the tube of fireplace – it means smaller load on whole combustion chamber.

Placed directly in feeding chamber, it guarantees high safety in case of clogging of the burner.

Taking heat from engines through the fan, provides a longer service life.

Unattended and maintenance-free operation even for laymans.

For easier and faster instalation.

Inside the burner or ceramic combustion chamber.

Remote control, acces via Internet and telephone application.

(preparing

Pellet burner Blaze Harmony includes automatic control unit with touch screen, possibility of controlling via internet and many other useful functions.

More information about automatic control unit here.

XS models with refractory combustion chamber

| Model | Power output |

|---|---|

| XS 16 | 4-16 kW |

| XS 20 | 5-20 kW |

| XS 26 | 6-26 kW |

| XS 36 | 8-36 kW |

| XS 50 | 10-50 kW |

| XS 70 | 15-70 kW |

| XS 100 | 20-100 kW |

| XS 150 | 30-150 kW |

| XS 200 | 30-200 kW |

| XS 250 | 35-250 kW |