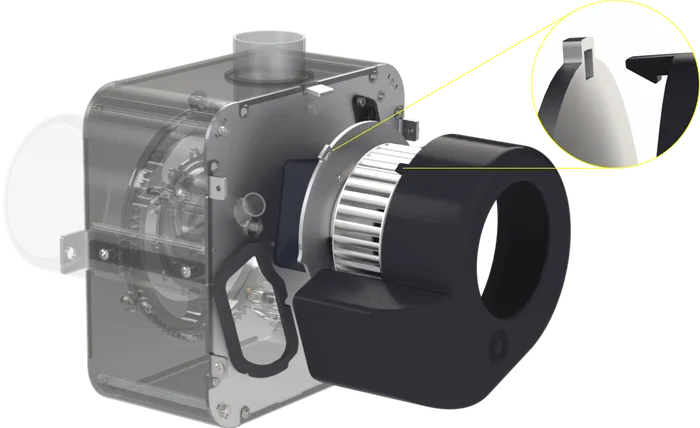

ecoMAX automatic control unit

The ecoMAX control unit provides convenient boiler control via an intuitive touchscreen display. It allows you to regulate output in the range of 30–100% without any loss of efficiency or combustion quality. The innovative technology of BLAZE HARMONY boilers ensures that even when the output is reduced from 100% to 50%, combustion remains just as efficient – it simply takes twice as long. At the same time, the controller monitors the maximum water temperature and protects the system from overheating.

The automatic control unit allows the boiler to operate at lower outputs (especially important in transitional periods) and to install a smaller storage tank, which leads to significant savings in both money and space.

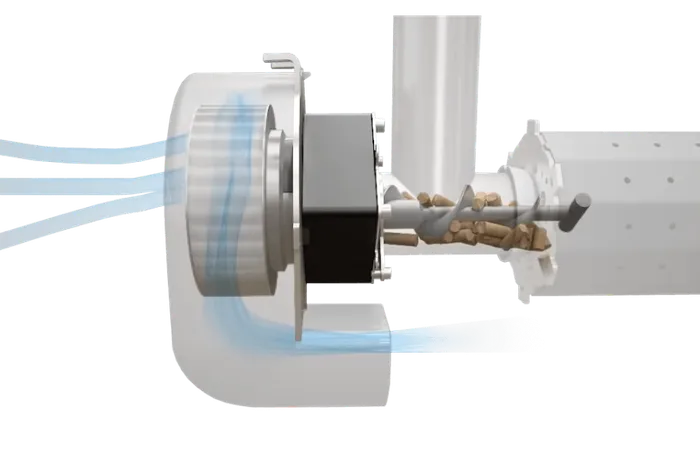

The controller also evaluates the O₂ values measured by the lambda probe and, based on these, controls the combustion air supply to maintain the set residual O₂ value while ensuring the highest possible combustion quality with lower fuel consumption.

The ecoMAX 960D control unit can be expanded with a P module, which extends the heating control options. This module not only allows you to control pellet combustion, but also to manage solar installations, heat storage tanks, and regulate the air supply to the boiler room. Thanks to these features, the module is also suitable for wood-fired boilers, to which advanced features can be added and their capabilities expanded.