All the advantages of gasification boiler BLAZE HARMONY are extended with a rotary burner with automatic transition to pellet burning.

This ensures the continuous operation of the boiler, with the option of a simple transition back to manual stoking when the pellet burner turns off automatically.

The special design of the burner with a rotary combustion chamber enables the burning of low-quality pellets.

This combination of options for burning various types of fuel in manual and automatic mode makes Hybrid BIOMASS® the most universal boiler on the market.

Allows to burn lower quality pellets.

Maintenance-free solution for burning pellets. It is sufficient to check it before heating season.

4 mm at its thinnest point. Only the refractory tube without welded parts.

Very simple and fast instalation and service of the burner. Quick acces to all components.

The longitudinal ball bearings transfer radial loads, ensuring smooth operation of revolutions of the burner, without any abrasion of metal/metal – load transfer at least on 50 balls (according to the size of burner). For user and service that means hihg service life (lower load of the bearings) and no abrasion of burner’s metal parts.

Patented mechanism, which ensures highest efficiency of combustion and possibility to set optimal combustion of various kinds of pellets. From output 25 kW, there is an option to regulate it thanks to the curtain.

Automatic cleaning of aeration chamber is common turning of combustion and aeration chamber. This method of automatic cleaning completely eliminates the need of manual cleaning. This eliminates periodic disassembling of the burner and service.

With this system all problems are eliminated, and proces of combustion is optimized by distribution of primary and secondary air.

There is an air curtain used in combustion chamber. This reduce the transfer of heat to burner and it means conservation of heat in the combustion chamber.

On which it relies the tube of fireplace – it means smaller load on whole combustion chamber.

Placed directly in feeding chamber, it guarantees high safety in case of clogging of the burner.

Unattended and maintenance-free operation.

| Boiler BLAZE | Usual boiler | |

| Adjustable output | YES | NO |

|---|---|---|

| Gravity connection | YES | NO |

| Operation without electricity | YES | NO |

| Possibility of combustion of loose fuels | YES | NO |

| Possibility of combustion of wet fuels | YES | NO |

| Possibility of automatic transition to pellet combustion | YES | NO |

| Burning time (max. filled chamber) | 3–8 hours | 2–5 hours |

| Usable stocking chamber volume | approx. 90 % | approx. 70 %

(front door) |

| Fuel consumption | 0,25–0,35 kg/kWh | 0,35–0,45 kg/kWh |

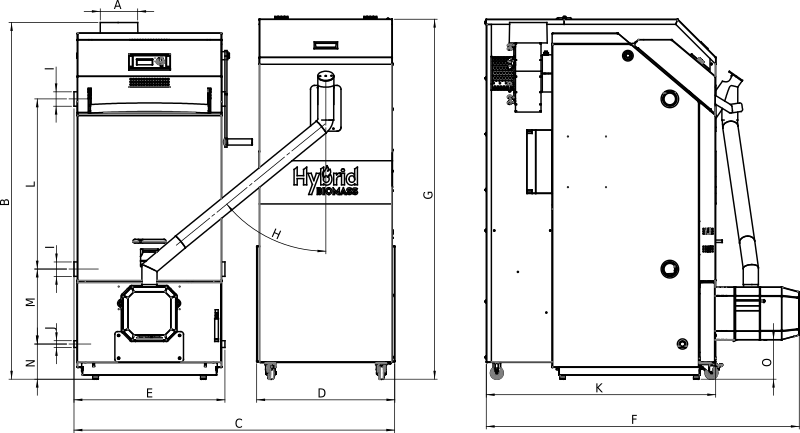

| HB 18 | HB 25 | HB 33 | |

|---|---|---|---|

| (mm) | (mm) | (mm) | |

| A | Ø147 | Ø147 | Ø147 |

| B | 1404 | 1404 | 1404 |

| C | 1262 | 1462 | 1462 |

| D | 544 | 544 | 544 |

| E | 594 | 794 | 794 |

| F | 1232 | 1253 | 1253 |

| G | 1417 | 1417 | 1417 |

| H | 51° | 51° | 51° |

| I | G6/4" | G6/4" | G6/4" |

| J | Q1/2" | Q1/2" | Q1/2" |

| K | 903 | 903 | 903 |

| L | 670 | 670 | 670 |

| M | 295 | 295 | 295 |

| N | 138 | 138 | 138 |

| O | 155 | 145 | 145 |

| HB 18 | HB 25 | HB 33 | |

|---|---|---|---|

| Nominal output - wood (kW) | 18 | 25 | 33 |

| Adjustable output - pellets (kW) | 5–18 | 6–25 | 6–25 |

| Nominal output - pellets (kW) | 18 | 25 | 25 |

| Efficiency (%) | 92 | 92 | 91 |

| Emission class | 5 | ||

| Ecodesign | YES | ||

| Energy class | A+ | ||

| Logs length (mm) | 330 | 500 | 500 |

| Pellet diameter (mm) | 6–8 | ||

| Stoking chamber volume (l) | 100 | 150 | 150 |

| Weight (kg) | 430 | 580 | 590 |

| Maximal operation pressure (bar) | 3 | ||

| Exchanger water volume (l) | 50 | 60 | 60 |

| Fuel silo volume (l) | 370 | 370 | 370 |

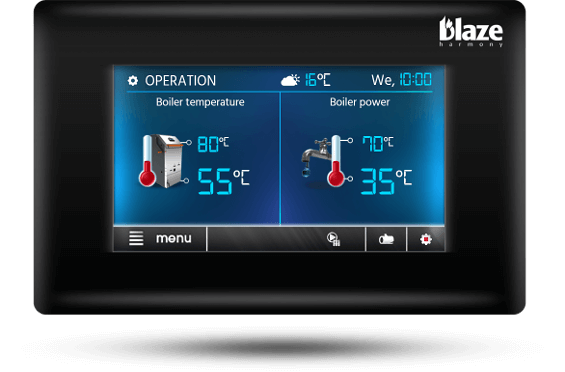

Sophisticated control software allows you to set the required boiler output in percentages and regulate the boiler with continuous operation. The range of possible output settings depends on the type of boiler installed. Setting of lower output will ensure a long period of combustion in the boiler, at a quality comparable to the quality at 100 % output.

This solution allows the boiler to operate at a lower output (especially important in the transition period), as well as the installation of a smaller buffer tank, saving expenses and space.

The controller also evaluates the O2 values measured by the lambda probe and controls the actuator of the primary, secondary, and pre-drying air curtain in order to maintain the set value of residual O2.

After connection of additional module this controller also controls the operation of the burner and pellet combustion, when it fluently modulates with burner output in whole range and thanks to that keeps required boiler temperature.

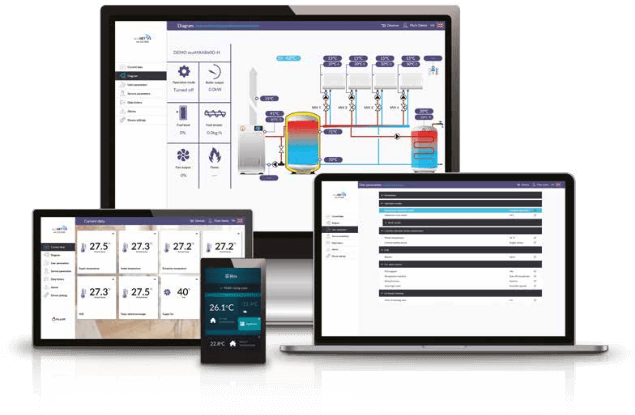

Internet system ecoNET provides to user option for remote control of the boiler and heating installation. Thanks to that user has possibility to change almost all parameters of boiler and heating system operation, but also view the history of the operation which is is displayed on a clear graph.

Remote acces to controller is possible from every device which is connected to internet, as it is tablet, laptop or mobile phone. Settings can be made via a web browser on www.econet24.com or through a mobile application which is available for Android and iOS.

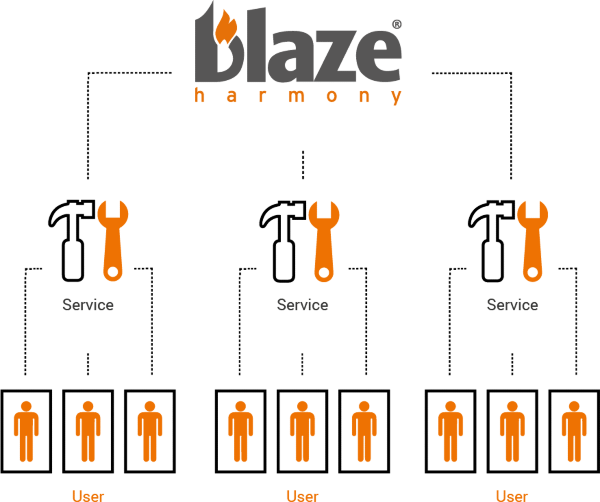

Online service. The internet system is not only for user. It is useful also for service company, which may have access to the boiler data and if neccessary the service company can change the controller settings. The internet system lowers the costs for service intervention significantly.

Remote control panel with room thermostat function ecoSTER TOUCH allows you to control and change the boiler’s settings from the place, where is the thermostat installed, for example the living room.

Allows controlling of another two mixing circuit and their pumps. Also it allows to control circulation pump for HDW.